Some things look worse — far worse — the closer you look at them. That’s the case with bar-end (or barcon) corrosion. The scourge of bar-end corrosion can happen to anyone, even to cyclists who are diligent about keeping their bikes in fine working order. It’s happened to Tamia’s Surly Long Haul Trucker. And it’s been found on a Soma Smoothie built by a mechanic friend of hers. Has it happened to your bike? You’d better check. Today. Because the consequences of not nipping bar-end corrosion in the bud can make you feel faint.

______________________________

by Tamia Nelson | December 3, 2017

I discovered the scourge of bar-end shifter corrosion when my Surly Long Haul Trucker was almost six years old, and with over 18000 miles on the clock. She’s — I named her Petra, and it suits her; she’s really been a rock — she’s my maid of all work for most everything from shopping to “amphibious” trekking. She’s held up well, despite the fact that a lot of the roads in my corner of the North Country are paved in gravel. And I’m not boasting when I say she’s been well-maintained. Petra is spoiled, in fact. Though she’s perfectly capable, I don’t ride her on winter roads. Liberal applications of salt and grit to local roads are killers of steel-framed bikes and ferrous components. I leave winter riding to my alloy mountain bike. But despite all the loving care I’ve given Petra — wiping her down after misty rides, keeping moving parts in fine fettle with just the right amount of lube — I was shocked discover that Petra had become …

A VICTIM OF BAR-CON SHIFTER CORROSION

The full horror of bar-con shifter corrosion must be seen to understand the sinking feeling I experienced in the pit of my stomach when I happened to discover it on Petra. Here are some photos of what it looks like:

Pretty dramatic stuff, eh? Yet the extent of the corrosion didn’t register until a week later. While I oil my shifters regularly, I don’t look at them closely — I don’t often wear my reading glasses when I work on my bikes — and since both shifters had a slightly rough finish right out of the box, my fingertips weren’t much help, either. These are rather feeble excuses, of course. I should have been more attentive. After all, I sometimes rest my hands on the bar-end shifters for short periods when I’m on the road, and my hands sweat inordinately. Farwell ends a 30-mile ride with bone-dry hands, whereas I finish the distance with gloves that are so sweat-soaked that I can wring salt water from them. And salt isn’t kind to aluminum. I suppose it’s also possible that the leather of my cycling gloves contribute, if the tanning process left residues behind. I’ll never know.

Once I grasped the extent of the problem, however, I lost no time in getting a closer look, using my camera’s macro capabilities to bring me in real tight. (A camera makes a fine addition to the mechanic’s tool box, by the way.) The photos above were the result, and they made it clear that I needed to…

REMEDY THE DAMAGE RIGHT NOW

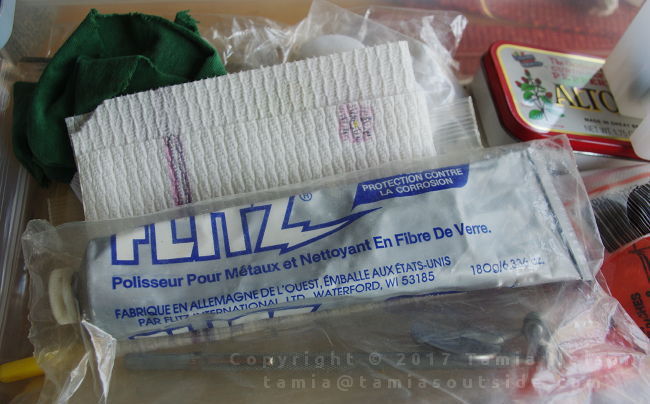

I turned to my store of gun-cleaning supplies, a relic of a time when I owned a lovely 20-gauge sidelock Arrieta side-by-side whose barrels had an unfortunate tendency to sprout surface rust after every heavy dew. The mainstay of my cleaning arsenal back then was a paste-like metal polish known as Flitz:

The maker suggests that Flitz works as well on aluminum as it does on blued steel, so I figured I’d give it a try. (I ran a test on a bit of aluminum scrap first, though, just to be sure that the cure wouldn’t be worse than the disease. Primum non nocere has relevance in fields far removed from medicine.) Cotton patches and a Scotch-Brite scrubber rounded out my anti-corrosion battle gear, with a few Q-Tips thrown in for mopping up operations in tight corners. I left the 0000 steel wool in the box, though. Using steel wool on aluminum is asking for trouble. Small fragments of steel work their way into the softer aluminum, where they remain. The result? Rusty aluminum, of course!

The rest was easy. I removed the plastic covers from the levers (they slide off with encouragement), then daubed a little Flitz on the worst spots and started scrubbing. And when I say “a little,” I really do mean a little. A very small amount of Flitz goes a long way:

And when a Q-Tip proved too bulky, I turned to a cotton patch wrapped around a toothpick. That delivered just enough of the sovereign remedy to even the tightest corners. Then it was time to start scrubbing:

After that, I wiped off the resulting gunge:

All that remained was to lay down a gossamer coat of light oil on the shifter pods, levers, and through-bolts by way of benison, before squeezing a drop or two of oil into all pivot-points:

Now I was ready to put the shifters through their paces, first on the workstand and then on the road. The result? A clean pass. Later in the year, I broke down the shifters into their component parts and was relieved to find that corrosion hadn’t spread to the internal workings.

The upshot? While my shifters will never regain their showroom shine — the pitting is too deep for that — I’ve succeeded in stopping the rot in its tracks. And you can be sure I do a better job cleaning Petra than I had been doing. Everything that my sweaty hands touches now gets a good wash, followed by a light dressing of oil. And what about you? Have you taken a close look at your shifters lately? If not, there’s no time like the present. I can’t be the only rider in the world with sweaty palms, can I?

DO YOU THINK CHECKING BAR-END SHIFTERS NOW IS TOO MUCH TROUBLE? THINK AGAIN

An ounce of prevention is worth a pound of cure, as the old saying states. It might be winter where you are, and your bike might be on the rack for the season, but take some time to check it right now. Even if the bike isn’t outfitted with bar-end shifters. And it it IS, then take a magnifying glass if you need to and make sure there isn’t any corrosion.

Why bother? If the photos above don’t convince you, then consider the experience of a friend of mine who is also a retired professional bike mechanic. He wrote this weekend to tell me he’d discovered corrosion on the barcons of the Soma Smoothie he built up some years ago. The corrosion is so bad on one of the cable ferrules that it’s become welded to the barcon pod and needs to be drilled out, with cables and casings replaced.

The bottom line? Spare yourself the trouble and expense of having to repair the results of corrosion. A little effort after each ride to inspect — and nip in the bud — corrosion before it becomes wide spread will pay off. Do it now.